Visit Report of WindEurope Offshore 2019

December 5th, 2019, Qingdao

The Chinese wind power delegation organized by Chinese Wind Energy Equipment Association (CWEEA) and Jiangsu Province Renewable Energy Industry Association attended WindEurope Offshore 2019 held at Copenhagen, and visited wind power related companies in Northern Europe from November 19th to 28th, 2019. The event is supported by Ministry of Foreign Affairs of Denmark - Invest in Denmark, the European Wind Energy Association (EWEA) and EASTWP.NET.

The delegation of 28 people consisted of 17 companies /and universities across the country, was led by Mr. QI Hesheng, Secretary-in-General of CWEEA, and Mrs. YONG Jingjing, Executive Deputy Director of Jiangsu Province Renewable Energy Industry Association. The delegation includes Chinese Renewable Energy Society , Jinke Renewable Energy Co., Ltd., Beijing Yitai Renewable Energy Technology Co., Ltd., Zhejiang University, Inner Mongolia University of Technology, Shandong University, Chongqing University, Sunshine Int’l Logistics, CRUN, BRIDGOLD Technology, Shandong CRRC Steel Structure, Anhui YuFeng Wind Power Equipment, Beijing ADC Wind Measurement Technology, Mintai Technologies Shanghai, and Primanex Corp etc.

The first stop is AQSystem A/S Company in Sweden on November 21th. Founded in 1989, AQSystem is a family-owned business focused on SoDAR. Pelle Hurtig, CEO of AQSystem, proudly credited their technology to his father, founder of the company, who was working in the Swedish military in the 1960s. The unique feature of SoDAR is that it can work in foggy conditions, and very clean areas where there are almost no aerosols, whereas lidars could not work because lasers are either strongly absorbed /or scattered by the humidity, or there is basically no laser back-reflection at all. SoDAR is therefore believed to be a very nice complementary alternative to wind measuring lidars in special circumstances.

Figure 1: Delegation in AQSystem

The delegation visited Norwegian Aker Solutions A/S on November 22nd, which has been designing offshore floating foundations since 1972, mainly for offshore oil rigs. As Knut Vassbotn (Senior Sales Manager, Wind) and Geir O. Berg (Product Manager, Wind) introduced, the Norwegian industry giant with proud history of 175 years has recently expanded its business into the offshore wind power area, mainly on floaters for wind turbines, power cables and all sorts of substations (subsea, bottom-fixed, and floating). They offer dynamic array cables which do not need torque-balancing, have no local twisting, and can withstand high longitudinal pressure, high impact and scouring, which may serve as very good examples for Chinese offshore wind power development.

Figure 2: Delegation in AkerSolutions

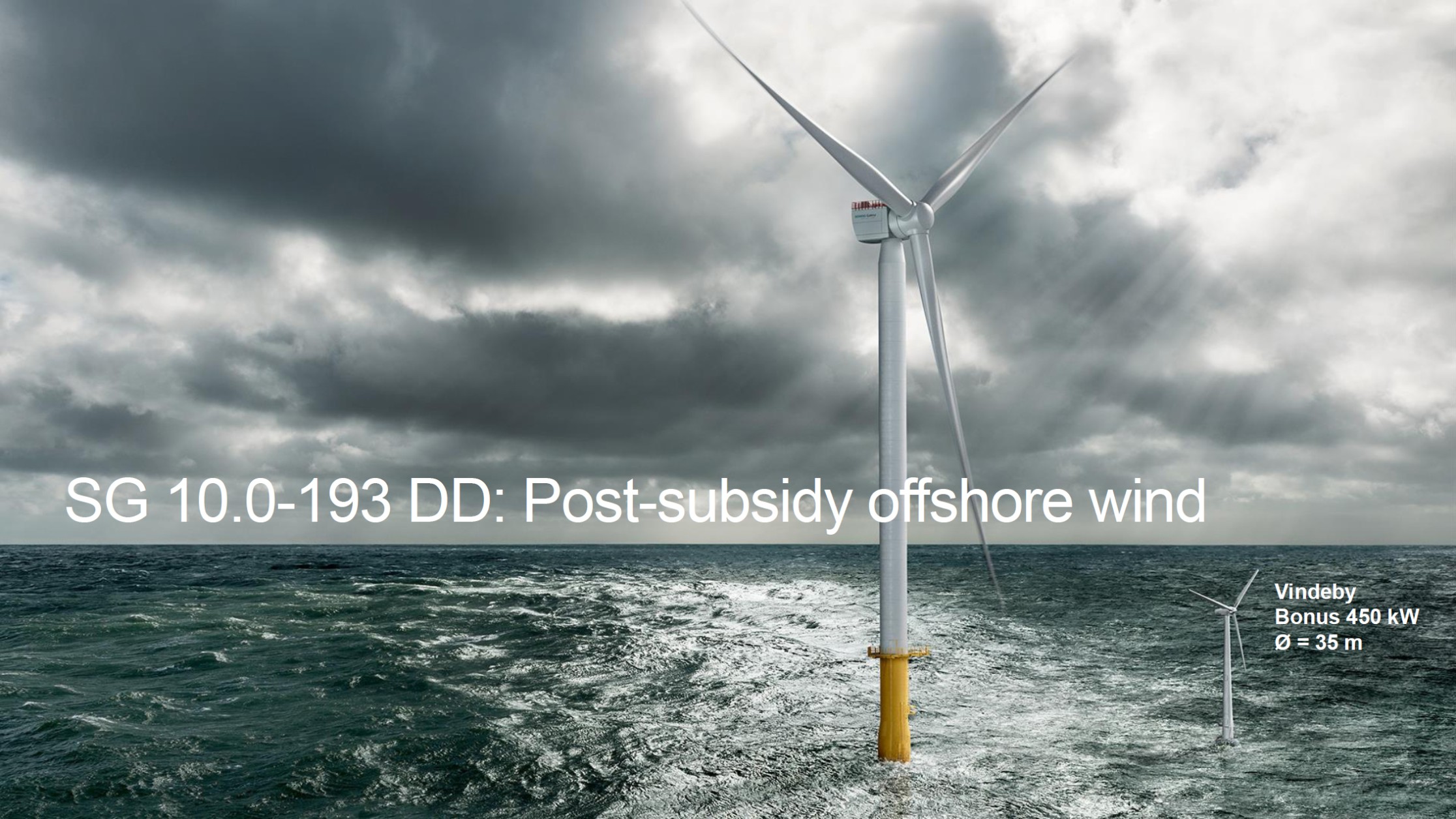

In the morning of November 25th, the delegation visited Siemens Gamesa Renewable Energy (SGRE) A/S. SGRE came into place in April of 2017 by merging Siemens and Gamesas wind business, is headquartered in Spain with its global R&D Center in Denmark. Their Product Manager, Christian Vestergaard, explained the overall corporation to the members of the delegation, and mentioned their three business units with Onshore having installed 81 GW since 1980, Offshore having installed 14 GW since 1991, and Service maintaining 58 GW. The Senior Product Manager of Offshore, Peter Esmann, then went on to introduce specifically SGREs offshore technologies and products. Peter pointed out their core technologies to be integral-blade for lighter and robust blades, direct drive (DD) generator for efficiency and less moving parts, full-scale converters for optimal grid compliance, and newly designed transformer which is deployed in nacelle instead of bottom for fast electrical completion and easier maintenance. To further showcase the robustness of their products, Peter told us their first offshore turbine installed in 1991 was actually an onshore Bonus 450 kW designed with 20 years of lifetime but in fact retired after continuously serving for 26 years. Peter showed the delegation a photo with the very first turbine Bonus 450 kW (rotor diameter 35m) and latest 10 MW turbine with rotor diameter of 193m, which is not only a powerful demonstrating of drastic technological advancement, but also a vivid illustration how offshore wind power has evolved during past 30 years.

Figure 3: Delegation in Siemens Gamesa Renewable Energy

SGRE arranged for the delegation to tour around their production facilities, training center and remote control center. Manned by only four staffs on a rotating daily basis, the single remote control center is non-stop serving more than 12,000 wind turbines around the world to ensure that any problems can be found, and analyzed through the big data at the very first time, and solutions can be sent to the worldwide local operation & maintenance personnel.

Figure 4: Photo of the delegation in SGRE campus

In the afternoon of November 25th, the delegation visited AH Industries A/S, a Danish company founded in 1962 that specializes in the supply of metal components, including castings and sheet metal, steel machining and other manufacturing solutions, as well as supply chain management industrial solutions for wind power component procurement and assembly. Adrian Willetts, Chief Marketing Officer and founder of AH Industries, told the delegation that they have established a subsidiary in Ningbo, China, to better serve the Chinese wind power industry.

Figure 5: The delegation in AH Industries

The delegation then visited Middlegrund Offshore Wind Farm in Copenhagen, Denmark on November 26th. As one of the earliest wind farms in Europe, it was built in 2000 with 20 turbines each having capacity of 2MW, hub height at 64m, rotor diameter of 76m, and 180m in separation. It adopts reinforced concrete single pile foundation with a total weight of 1800 tons and a water depth of 612 m. Arranged in lines, Middlegrund Offshore Wind Farm was the largest offshore wind farm in the world at that time. It can provide electricity to more than 30, 000 households in Copenhagen and reduce 68 million kilograms of carbon dioxide emissions each year.

In Denmark, the safety rate of power supply can reach 99.996% due to the integrated and intelligent wind power network, which can significantly reduce risks. Danish offshore wind power is already more cost-competitive compared against onshore wind and solar. Its expected that Danish offshore wind installation capacity would exceed 5 GW by 2030 with 1 GW already under construction.

Figure 6: The delegation in Middlegrund Offshore Wind Farm

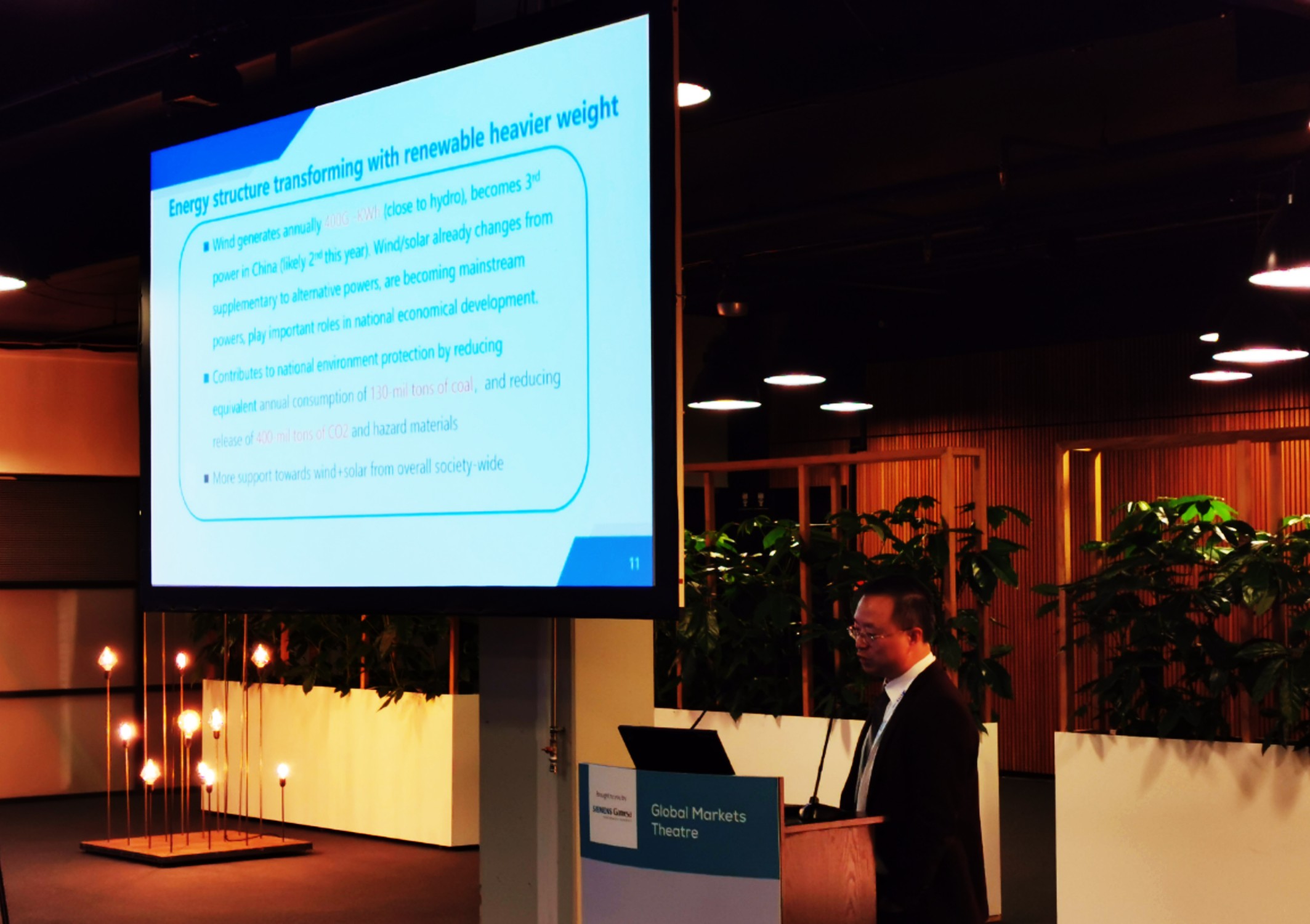

The delegation attended the WindEurope Offshore 2019 held at Copenhagen on November 27th. Dr. Zhao, President & CEO of Primanex Corp, was invited to the Global Markets Theatre -China special session, and made presentation titled as the current status and development of Chinas offshore wind power industry on behalf of the delegation, CWEEA, and Jiangsu Province Renewable Energy Industry Association. The delegation was also invited to an informal talk with MHI Vestas. MHI Vestas is a 50% joint venture between Vestas and Mitsubishi Heavy Industries of Japan, headquartered in Aarhus. It has accumulated extensive experiences in offshore wind power in Europe and is now actively expanding in Asia-Pacific region.

Figure 7: Dr. Zhao and Chinese colleagues presented in Global Markets Theatre -China

Figure 8: The delegation at MHI Vestas booth

The purpose of this visit is to understand the current status and trends of European offshore wind power development, provide inspirations for Chinas large-scale offshore wind power development, and help Chinese wind power players to expand their international markets and strengthen the international cooperation.